Shimano SIL-TEC Chain Technology

Digital Integrated Intelligence

Electric drivetrain with the best of brains and brawn.

The revolutionary DI2 shifting system solves the challenges drivetrains present to the power-delivery equation in cycling. DI2 gives you instant, accurate, lighting-fast shifts the first and every time, at the push of a button. Even in the most extreme conditions, shifting is precise and controlled. You can change gear even under heavy load while climbing or accelerating. With DI2, you are in complete control.

Main Features

Fully customizable through E‑TUBE

Quick and smooth shifting 'under' high pedaling torque

Super long battery life

Reliable in all weather conditions

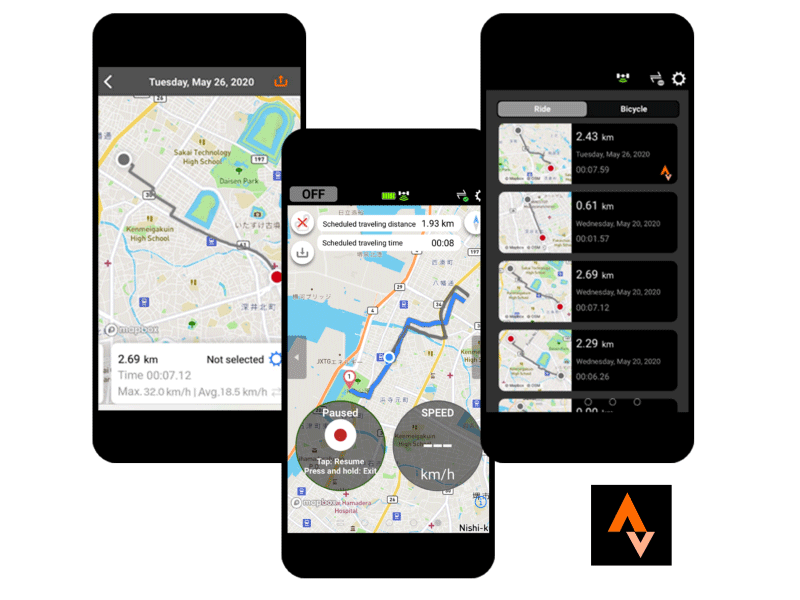

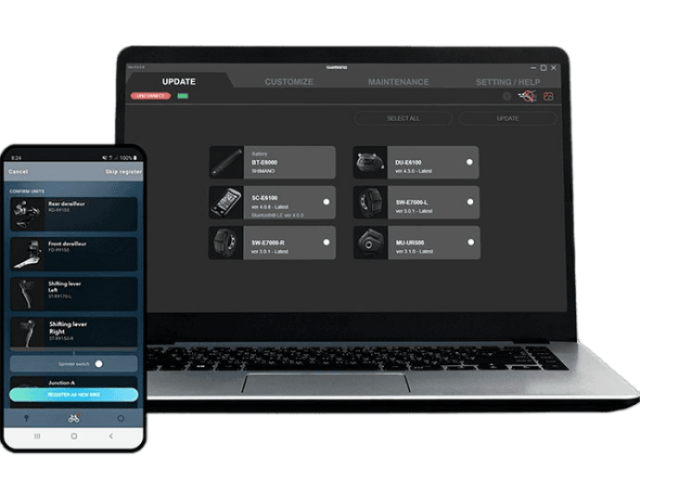

E-TUBE PROJECT Cyclist APP

CUSTOMISABLE SETTINGS OFF THE BIKE

SHIMANO’s E-TUBE PROJECT Cyclist application allows you to customize your bike, update firmware, and maintain it by connecting wirelessly to your bike. For more detailed bike maintenance, home and shop mechanics can connect their bikes by wire with E-TUBE PROJECT Cyclist for Windows application.

Main Features

Firmware Update

Easily update to the latest firmware with the user-friendly interface

DI2 Setting

Design your favorite DI2 gearshift sequence using Synchronized Shift

2 Assist Profiles

Set two e-bike assist profiles to your preference, and customize the assist characteristics according to the riding situation

Derailleur Adjustment

Easily adjust both front and rear derailleurs via application

E-TUBE RIDE

FROM A SMARTPHONE TO THE CYCLING COMPUTER ON THE BIKE

SHIMANO’s E-TUBE RIDE application allows you to visualize your ride with a route map to your destination, a real time ride data display, and to record data on your smartphone while you are on the bike. You can also seamlessly upload your ride data to Strava.

HOLLOWTECH II

Providing the best balance of stiffness, strength, weight and rotating performance

HOLLOWTECH II technology is focused on producing a superior crankset which maximizes a rider’s power transfer. A rigid crankset ensures pedaling efficiency while light weight aids in cycling longer distances with less effort.

Balancing these demands led SHIMANO to develop HOLLOWTECH, an ultra-light, hollow crankarm that uses the company’s proprietary forging technology to maintain rigidity. HOLLOWTECH II takes the technology a step further by integrating the bottom bracket axle with the right crankarm for increased stiffness and weight savings.

Main Features

The Perfect Mix

Best balance of stiffness, strength, weight and rotating performance

Super Durable

Increased durability due to high precision sealing

ICE TECHNOLOGIES

Stay cool under pressure with Shimano ICE-TECH brake technologies. Designed to dissipate brake heat and provide the most consistent, reliable, and quiet braking available, ICE-TECH helps increase rider confidence, whatever the conditions.

ICE TECH’s 3-layer rotor construction of stainless steel and aluminum results in a 100-degree Celsius reduction in heat compared to standard rotors. This works together with thermal insulating pistons in the calipers and radiated fins on the pads to further reduce the heat of the rotors and brake fluid while also extending pad life.

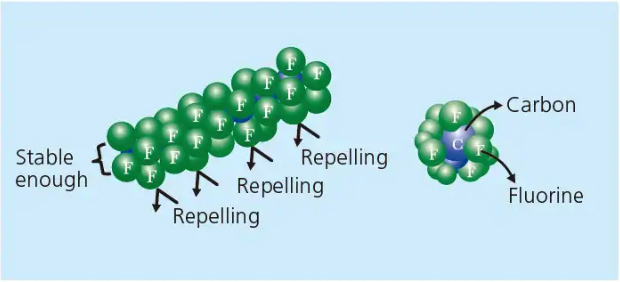

Amidst all the technological wizardry of modern drivetrains, it’s easy to overlook one of the most important components of the group. The chain keeps the drivetrain running smoothly, overseeing the transfer of power while holding the system together. Much more than just the connection between the cranks and the cassette, the chain is a perfect loop of interconnected links, each performing with equal amounts of strength and precision.

Shimano boosts chain performance by using an ultra-low friction surface treatment called SIL-TEC to its top tier chains. This process involves applying imbedded fluorine particles to the chain using an advanced plating process that is superior to the simple coatings used in other chains. The benefits of SIL-TEC are significant to the performance of your chain and lead to a better ride experience from start to finish.

SIL-TEC delivers increased water and dirt resistance, which means the chain remains cleaner and dryer in all riding conditions. This enhances drivetrain efficiency, improves shifting performance, and allows the chain's lube to last longer with little interference from the elements. Additionally, SIL-TEC sheds mud 30% more effectively than chains with common Zinc-Nickel (Zn-Ni) plating treatments so riders can focus on the trail ahead and shift with confidence in all conditions.

Shimano SIL-TEC chains also help reduce friction in the drivetrain thanks to the slippery surface treatment. Chains that glide better over the chainring and cassette teeth are more efficient, so less energy is wasted in the mechanical process, and more power is transferred through the drivetrain. This means riders can use less energy and ride faster.

The SIL-TEC treatment also increases a chain’s lifespan, especially when riding in mixed conditions. The slippery, efficient chains accumulate less wear and tear as they glide across the drivetrain so they stay newer longer. Chains with SIL-TEC are 20% more resistant to abrasion and will help keep your entire drivetrain running smoother for longer.

Each feature of Shimano’s SIL-TEC treatment contributes to a bike that pedals smoothly and quietly, which riders will enjoy each time they ride. In quantitative terms, SIL-TEC brings a reduction in chain noise of -2.7 decibels thanks to a 60% reduction in rotation-based sliding friction. That’s smooth silence you can hear and feel.

Shimano uses its SIL-TEC surface treatment on many top-tier products, including XTR mountain bike chains and Dura-Ace road chains. Often an afterthought on spec sheets and in riders’ minds, the chain is actually a massive effort of engineering and manufacturing. It’s an integral part of any drivetrain and is one of the easiest and most cost-effective upgrades you can make for your bike.

HYPERGLIDE+

Born from decades of precision-engineered drivetrains, HYPERGLIDE+ is the latest iteration of Shimano’s premium shifting technology. Now available on DURA-ACE and ULTEGRA 12-speed road cassettes, HYPERGLIDE+ lets riders shift smoothly and securely up and down the cassette without letting off the gas.

HYPERGLIDE+ is made up of two linked elements. Advanced shift ramps in the cassette combined with extended inner plates on the chain deliver maximum efficiency and incredibly smooth shifting performance virtually anywhere.

Never hesitate to shift throughout your ride knowing that HYPERGLIDE+ has the unique ability to perform any gear change, anytime you need it.

SPD-SL

Discover the efficient power transfer and secure connection of Shimano's SPD-SL road cleat and pedal platform. Featuring an extra-wide, low-profile design, SPD-SL cleats distributes energy evenly and efficiently from your foot to the pedal for long-lasting performance.

Designed for seamless integration with Shimano footwear, the SPD-SL cleat and pedal deliver efficient power transfer and personalization features so you can tune your fit. Easily customize your connection with the bike by adjusting the pedal spring tension and by selecting from three cleat options that feature different levels of float and pivot point locations.

System-engineered, rider-tuned. Shimano's SPD-SL pedaling platform means more comfort for long days on the bike. Engineered for the future, dialed from day one.